Conveyors are utilised in storage facilities just about everywhere to maximise productivity and maintain business running smoothly. For many businesses, they are at the heart of manufacturing. If your conveyor goes down, business comes to a standstill. Whether you’re wanting to invest or you currently have one, it’s important to know as much as you can regarding this equipment that plays such a crucial role in manufacturing to avoid these unwanted breakdowns.

What Conveyor Systems Can You Obtain?

There are various different sorts of conveyor systems readily available, depending on your requirements. Some various kinds consist of:

- Belt conveyors

- Gravity conveyors

- Flat belt conveyors

- Slat conveyors

- Bucket Conveyors

There are far way too many for a total listing right here, however if you’re wanting to purchase a conveyor, you ought to seek out the different kinds to see which would best suit your company. This is necessary as each kind of conveyor will be suited to various purposes. Conveyors are mainly utilised for transport, however they can also have various other uses like loading and cooling.

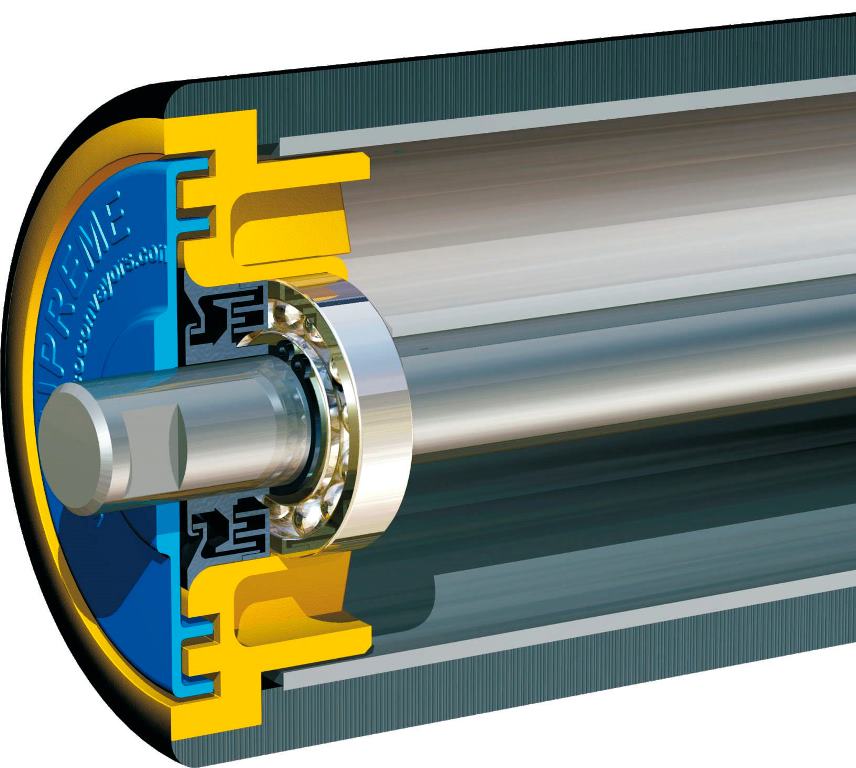

Gear Rollers To Cross Clamps

There are several parts to a conveyor system, and precisely how they’re made varies from type to type. Several of the raw materials you should know of are wheels, clamps, belts and rollers. These will certainly all be unique depending upon your conveyor, for example there are several types of rollers (gear rollers, gravity rollers, stainless steel rollers, and much more) that completely change how the conveyor functions. Recognising the different parts of your conveyor is vital to keeping it running at its best.

Looking After Your Conveyor System

If you have a conveyor system, you must know how you can be taking appropriate care of it. You should only be making use of materials suitable for your conditions. For instance if your conveyor enters into regular contact with water you ought to be using stainless-steel and plastic. You should furthermore have an annual service of your conveyor, and do everyday checks in the meantime to make sure every little thing is working well. Any person who works with your conveyor system must be appropriately educated so as to avoid damage through abuse. Taking care of your conveyor is key to preventing break downs.

There are numerous Conveyor Rollers online resources in the UK, if you’re looking to find out more or values this web site is a great place to start www.conveyorrollers.co.uk

Keeping Safe When Utilising Conveyors

If you have a conveyor operating in your warehouse, you’re going to want to make sure no one gets into a mishap around it. For this reason it’s incredibly important that all members of staff collaborating with it know the safety and security procedures, and can properly and securely run the conveyor. If they are not knowledgeable about the risks, they won’t be so likely to be able to prevent them. You should also have a functioning ‘shut down’ switch at normal periods in case of emergency. The correct security devices should be used at all times by anybody near the conveyor system. By watching, you can help to stop entirely preventable mishaps.

Conveyor systems are extremely valuable in business, if you recognise the best ways to use them correctly. The initial step to being able to utilise them to their optimal capacity is understanding exactly how they work– you need to understand every sprocket roller, clamp and screw in your conveyor. This will certainly help you to maintain the whole system. You should also only man the conveyors with fully-trained employees, and guarantee that correct safety and security methods remain in place. When your conveyor is being used appropriately, your whole production will come to be more efficient.