Maintaining your conveyor system in good shape is necessary to having a smooth assembly line. If your conveyor drops, every little thing stops, and you could end up losing money from simply a few mins of no movement. It’s simple to comprehend why taking preventative steps to prevent this is a must!

Inspect On A Daily Basis

Checking your conveyor systems daily takes very little time and could help stop little issues from becoming significant ones. Walk around and examine your equipment; try to find oil leaks, uncommon sound, and other signs of wear as well as damages. You must also guarantee that the conveyors aren’t strained, and that all equipment and safety and security gear is being utilised properly and working effectively. These fast checks are a must to preventing future catastrophes.

Give Appropriate Training

If your drivers typically aren’t appropriately trained, they’re not going to be so proficient at running the conveyors and failures are far more likely. You ought to educate all your drivers in the running and upkeep of the conveyors, and they ought to all have a comprehensive knowledge of the equipment entailed. They could then likewise better discover any small issues or abnormalities, and either know how to repair them themselves or report them to other team member swiftly. It is very important to maintain great communication with all operators to get information on the running of the conveyors and also identify any kind of spaces in their expertise.

Original Equipment Manufacturers: Precisely How They Can Help

You should obtain an OEM (initial devices supplier) in at least yearly to do a thorough check of all your conveyors. As they produced the devices, they’ll have the most effective expertise on how it must be working. They’ll fully service your conveyor systems and be able to identify any kind of tiny faults or damages that you might have missed. They can also aid you to take care of your equipment, and assemble a maintenance list so you could correctly maintain it.

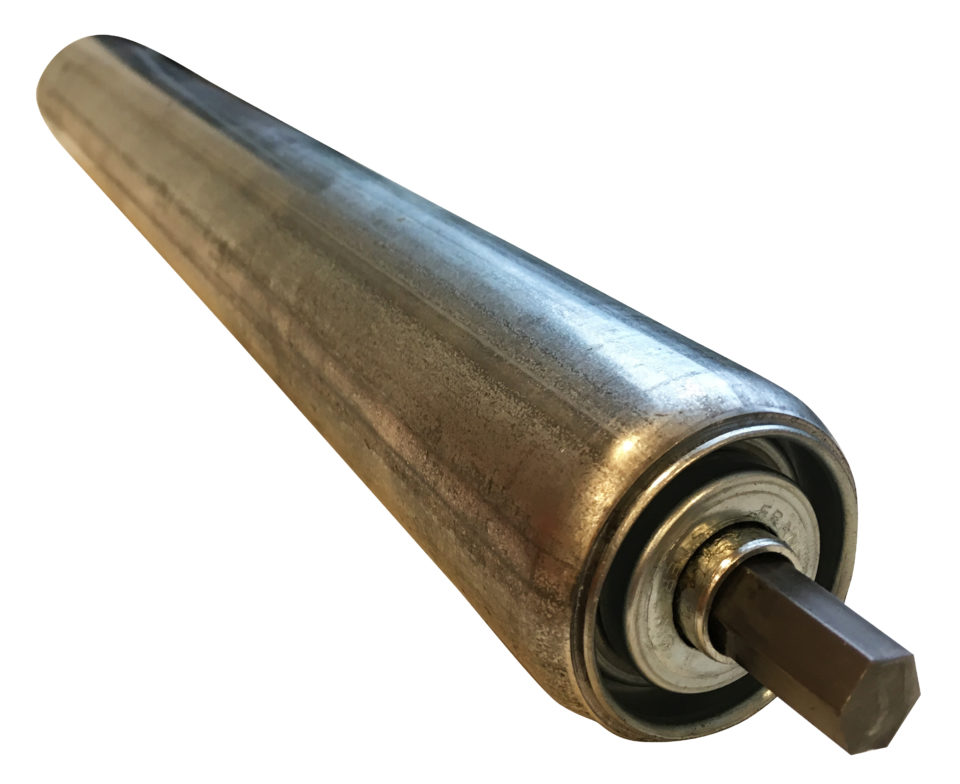

Maintain Your Conveyor Rollers In Top Shape

Maintaining your conveyor rollers in good shape is important to maintaining the whole conveyor running. Maintenance will vary depending upon the product and type of your rollers so you should recognise how to care for your own particularly. For all rollers, you must be checking for signs of visible damages and wear frequently. You ought to likewise make sure that they’re secured effectively– no loosened bolts– and that they’re lined up correctly.

Don’t Damage Your Conveyors Through Misuse

Running your conveyors appropriately is, of course, important to maintaining them from falling short. The leading misuse is straining your conveyors for faster manufacturing, however in the end this will only antagonise you when they break down. Though it can be alluring, be sure not to overload or run them as well quick. You must reduce your conveyor down routinely, as running it frequently at full speed could wear down the equipment. Knowing ways to maintain your conveyor running happily is the most important step to preserving it.

You should watch in the upkeep of all your equipment, specifically conveyor systems. By maintaining regular checks and understanding how to preserve the different components, such as conveyor rollers, you’ll assist your entire assembly line to continue running efficiently and effectively.

This excellent website www.conveyorrollers.co.uk offers quite a bit more information on the subject of motorised roller.